Introduction

3D scanning involves creating three-dimensional digital models of objects by recording their shape and spatial attributes. This method converts real objects into digital equivalents, which can then be analyzed, modified, or even replicated using technologies like 3D printing.

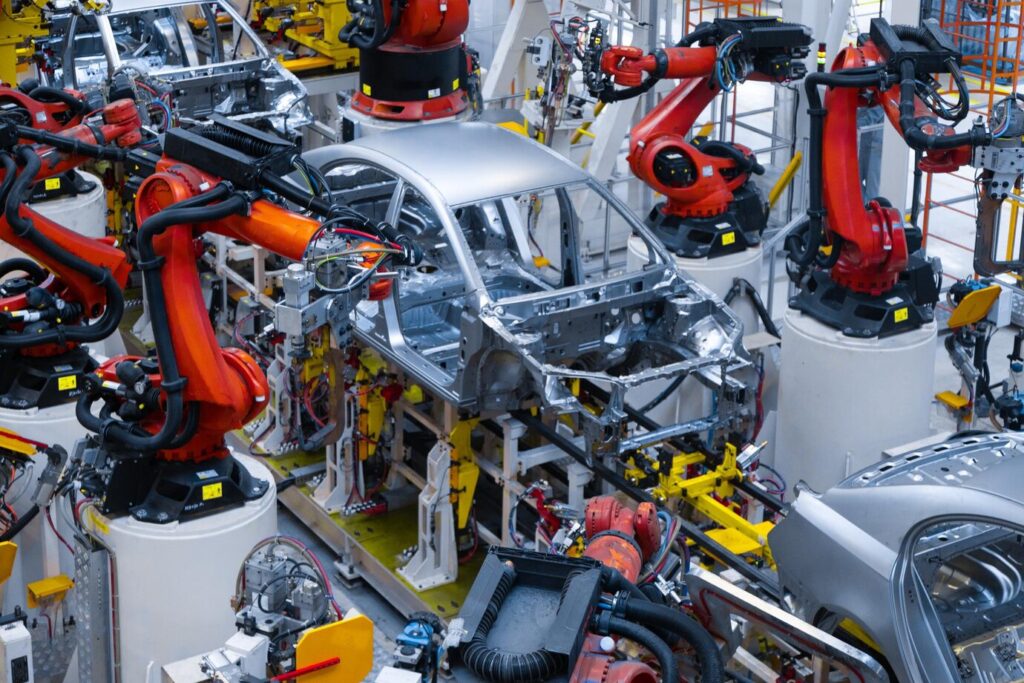

In the automotive realm, 3D scanning represents a monumental leap forward. It enables engineers and designers to precisely and swiftly examine vehicle components, develop prototypes for new parts, or adjust existing ones. This substantially accelerates the design process and conserves resources.

The shift 3D scanning has introduced to automotive production mirrors the transformation that computer-aided design (CAD) brought to drafting and design years ago. Beyond streamlining the design and modification process, this technology also ensures each manufactured vehicle meets high-quality standards due to the detail and accuracy it offers.

History and Evolution of 3D Scanning in the Automotive Industry

The Genesis of 3D Scanning

3D scanning technology first appeared in the mid-20th century. However, it gained traction in the 1980s as computer technology and software evolved. Initial 3D scanners were sizable, pricey, and lacked the precision of today’s devices. Yet, even these nascent systems showcased immense potential across engineering, medicine, and art.

Adapting to Automotive Needs

- 1980s-1990s: In the early stages, 3D scanning was predominantly used for quality control and analysis of distinct parts, especially in sports and luxury vehicles that demanded high precision.

- 2000s: Technological enhancements ushered in a wave where car manufacturers increasingly turned to 3D scanning for creating model prototypes. This revolution cut down prototype production time and costs while enhancing design quality.

- 2010s: Merging 3D scanning with computer-aided design (CAD) systems opened new vistas. Transferring physical objects into a digital realm, modifying them, and translating them back into the physical world through 3D printing became straightforward and swift.

- 2020s: Currently, 3D scanning caters to a plethora of applications in the automotive sector. From design, manufacturing, road accident analysis, to classic car restoration, the scope is vast.

Key Benefits of Using 3D Scanning in the Automotive Industry

- Enhanced Accuracy and Part Quality: 3D scanning allows for the precise digitization of physical objects. Such detailed reproduction ensures improved component durability and quality. Manufacturers can sidestep expensive errors stemming from inaccuracies or flaws.

- Streamlined Product Development: Previously, prototyping or design modifications could span months or even years. Now, 3D scanning equips manufacturers with rapid 3D models, enabling on-the-go adjustments. This pace not only propels the design process but also allows swifter market entries for new models or upgrades.

- Resource and Material Conservation: The precision of 3D scanning minimizes the production of multiple physical prototypes, yielding material savings. With a precise digital representation, material usage in mass production can be optimized, thereby reducing waste and production costs.

Practical Application Examples

- Design and Prototyping of New Car Models: For instance, Tesla employs 3D scanning for its car model prototypes, enabling quick validation of a vehicle’s design and aerodynamic properties.

- Quality Control and Part Inspection: BMW, for example, leverages 3D scanning for rigorous quality checks of parts supplied by vendors.

- Restoration and Modification of Classic Cars: A specialized restoration firm employed 3D scanning to recreate parts for a rare 1937 Bugatti.

Current Trends and the Future of 3D Scanning in the Automotive Industry

- Integration with Advanced Technologies: Contemporary demands lean towards automation and sophisticated analysis. By melding artificial intelligence and machine learning with 3D scanning, analysis accuracy, error detection, and design optimization receive a significant boost.

- Evolution of Portable and Affordable 3D Scanners: The burgeoning demand for mobility and affordability has spawned the advent of compact, portable, and cost-effective 3D scanners. This democratization ensures accessibility for both large manufacturers and small entities.

Conclusion

3D scanning has unequivocally showcased its intrinsic worth to the automotive sector, becoming an indomitable aspect of modern manufacturing. This tool catalyzes development, heightens quality, and fosters innovation at every vehicle creation juncture.

Gazing into the future, 3D scanning holds untapped potential. The amalgamation of cutting-edge technologies and the evolution of handheld devices promises further breakthroughs and innovations in the automotive arena.