Introduction

3D scanning technology, emerging in the late 20th century, has witnessed profound transformations. Initially utilized in aviation and medicine, it has since permeated various sectors, notably, the realm of jewelry. Today, 3d scanning for jewelry stands as an indispensable facet, offering unparalleled precision in crafting unique pieces. It paves new avenues for jewelry designers, letting them translate even the boldest of ideas into impeccable artifacts.

Key benefits of 3D scanning for jewelry making

3D scanning heralds a paradigm shift in jewelry creation, introducing multiple invaluable advantages:

- Increased accuracy: Contemporary 3D scanners, integral to 3d scanning for jewelry, pinpoint even the tiniest intricacies, enabling creations of unmatched precision.

- Reduced time: What used to take weeks for prototyping jewelry now takes considerably less time, thanks to 3D scanning. This agility enables jewelers to swiftly introduce new collections and adapt to market dynamics.

- Personalization: 3D scanning facilitates the customization of designs as per individual preferences, ensuring every jewelry piece resonates with its owner’s essence.

- Quality control: The finished jewelry can be juxtaposed with its original 3D scanned model, ensuring consistency and high standards.

Such benefits solidify 3D scanning’s role as an irreplaceable asset for jewelers who aim for unparalleled artistry.

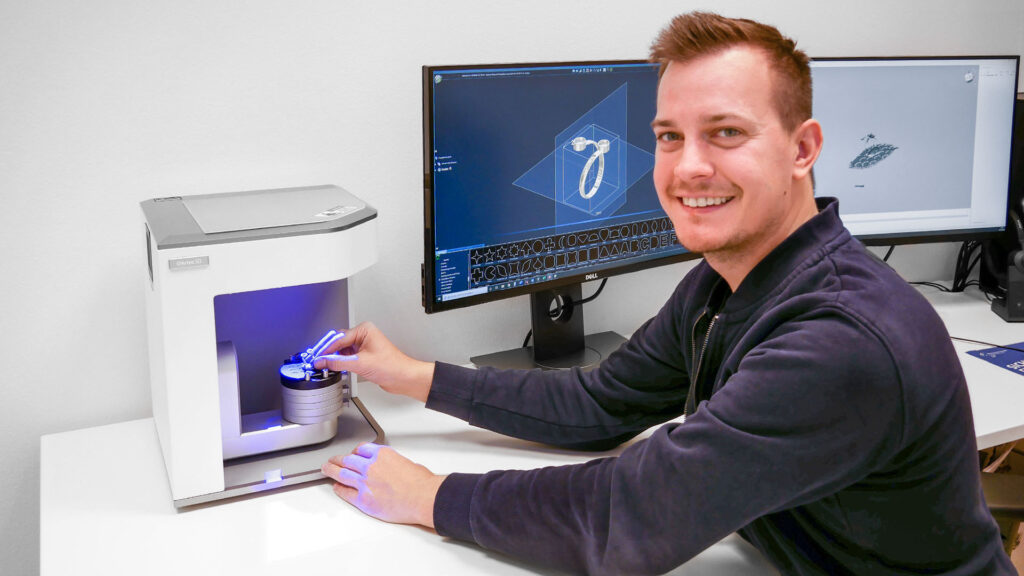

Technical aspect: how 3D scanning works

3D scanning manifests a physical object digitally in a three-dimensional space. It predominantly operates on the principle of light interplay with the object and subsequent data analysis.

- Principle of 3D scanners: There’s a plethora of 3D scanners, but most function by projecting light and analyzing the reflections. Laser scanners, for instance, measure the time taken for a laser beam to bounce back, while stereoscopic scanners capture different object angles using multiple cameras.

- Equipment selection: Choosing a scanner hinges on the task at hand. High-resolution desktop 3D scanners excel at capturing detailed jewelry models, while larger objects might require portable or industrial versions.

A nuanced grasp of 3D scanning’s technicalities ensures its effective incorporation, guaranteeing premium outcomes.

Application of 3D scanning in jewelry production

3D scanning technology infuses innovative methods into jewelry production, broadening creative horizons.

- Prototyping: 3D scanning simplifies prototype creation, ensuring accuracy even before production begins.

- Recreating jewelry: 3D scanning breathes life into lost or damaged jewelry, offering restoration that mirrors the original.

- Design: 3D scanning empowers jewelers to toy with unconventional designs, textures, and forms, pioneering distinctive masterpieces.

Such capabilities reinforce 3D scanning’s significance in shaping the future of jewelry craftsmanship.

Examples of successful application of 3D scanning in the jewelry industry

3D scanning’s inception into the jewelry sector has witnessed overwhelming adoption. A few instances include:

- Tiffany & Co.: This iconic brand seamlessly blends 3D scanning in its design ethos, refining prototypes and enhancing product quality.

- Boucheron: They harness 3D scanning to resurrect historical jewelry pieces, relying on archival photos and sketches.

- Independent jewelers: Many, like Anna Schultz, craft unique jewelry leveraging 3D scanning, encapsulating the natural allure of minerals and plants.

Such instances underscore the synergy between traditional craftsmanship and modern technology.

Potential Problems and Limitations of 3D Scanning in the Jewelry Industry

Despite its merits, 3d scanning for jewelry isn’t devoid of challenges:

- Accuracy and resolution: Scanning intricate designs or complex geometries can pose hurdles, even with advanced scanners.

- Material limitations: Reflective or transparent materials resist accurate scanning due to their inherent properties.

- Technological Complexities: While simplifying several aspects, 3D scanning introduces unique challenges – from software compatibility to staff training.

Nevertheless, these challenges are surmountable, ensuring 3D scanning remains pivotal in contemporary jewelry crafting.

Conclusion

3D scanning is sculpting the future of jewelry, unveiling boundless design and production prospects. While its benefits are undeniable, it necessitates a meticulous approach for seamless integration. For forward-thinking businesses, embedding 3D scanning is undeniably a transformative stride.